ECS Technology

Each time a part (or batch of parts) is to be magnetized, a fixture must be chosen as well as a magnetizer which is capable of delivering the proper amount of energy into the fixture. If the energy level of the magnetizer is too low, the field created in the fixture will not fully magnetize (saturate) the magnet part. If the energy level of the magnetizer is too high, the fixture may overheat or fail due to mechanical stress. In the past, companies have dealt with this by either keeping a variety of magnetizers on hand (with varying energy levels) or by adding and removing capacitors from their magnetizer.

ECS (Electronic Capacitance Switching) is our solution to this problem. With an Oersted Technology magnetizer, the user can electronically select the capacitance necessary for the task at hand, as well as the charging voltage. The capacitance and voltage can be adjusted until the right combination is found for the application. This allows one machine to mimic a small magnetizer, a large magnetizer, and everything in between.

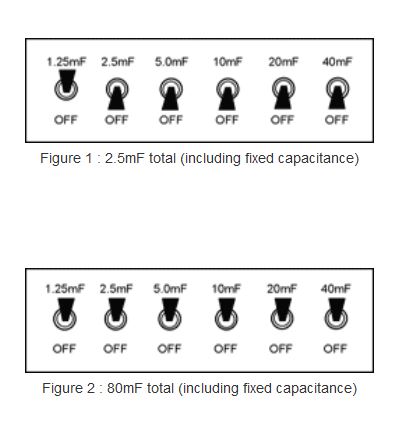

The following two examples demonstrate how capacitance is selected on an Oersted Technology magnetizer:

Example 1: When an ECS select switch is on (with the toggle switched flipped to the upper position), the magnetizer’s charging voltage will be sent to the capacitor bank associated with that the switch. In Figure 1, the 1.25mF select switch is on and the other five switches are off, so only the 1.25mF capacitor bank is selected. In addition to any selected banks, the magnetizer contains an unswitched capacitor bank. The total capacitance selected for charging is 2.5mF.

Example 2: In Figure 2, all of the ECS select switches are on. Therefore, all six of the magnetizer’s capacitor banks (as well as the fixed bank) will be charged by the selected charging voltage. The total capacitance selected (plus the unswitched 1.25mF bank) is 80mF. This is the maximum capacitance available on the Model 340B magnetizer.